Call Us

08045476045

Precast Compound Panel Mould

Precast Compound Panel Mould Specification

- Load Capacity

- Handles up to 1200 Kg wet concrete load

- Color

- Grey, as per finish / can be customized

- Features

- Corrosion Resistant, Smooth Finish, High Strength

- Machines Type

- Manual/ Automatic Precast Casting System Compatible

- Thickness

- Panel Thickness 50 mm (Mould Plates 6-8 mm)

- Installation Type

- Detachable/Clamped Type

- Application

- Construction, Boundary Wall, Fencing Panel Manufacturing

- Form

- Solid Fabricated Steel Structure

- Material Grade

- IS 2062 / EN Series Steel

- Usage

- Precast Compound Wall Production

- Purity

- N/A (Not applicable to steel moulds)

- Product Type

- Precast Compound Panel Mould

- Main Material

- High Grade Steel / Mild Steel

- Surface Treatment

- Polished / Anti-Rust Coated

- Size

- Standard and Custom Sizes Available (e.g., 7 ft x 1 ft)

- Weight

- Approx. 85-120 Kg (depending on size)

- Feature

- Reusable, Durable, High Precision

- Shape

- Rectangular Panel Mold (with Grooved Design)

- Mobility

- Optional wheels for easy movement

- Maintenance

- Low maintenance, easy cleaning

- Temperature Resistance

- Up to 350°C (temporary exposure)

- Panel Output Per Cycle

- 1 Panel

- Lifespan

- More than 500 cast cycles with proper maintenance

- Joint Type

- Bolted / Welded Construction

- Compatibility

- Suitable for vibration tables

- Surface Finish Quality

- Mirror Polished (for smooth productivity)

- Customization

- Size and pattern customizations available

Precast Compound Panel Mould Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- Unit

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS PER REQUIRED

- Main Domestic Market

- All India

- Certifications

- ISO2001:2015

About Precast Compound Panel Mould

Pre-cast Compound Panel Mould

Present as a client-centric organization, we are reliably manufacturing and supplying superior range ofPreCast Compound Pole. The precisely designed range is perfectly used for the construction process to give an excellent strength to the building or structure while giving it a proper shape. We construct this range by selecting an excellent range of materials and high end techniques as per industrial laid norms. Our quality analysts check thisPreCast Compound Poleon different parameters including rigidity, performance and durability in order to deliver a defect free range to our clients.

Features:

- Accurate dimensions

- Weather proof

- Sturdy construction

GreenStone

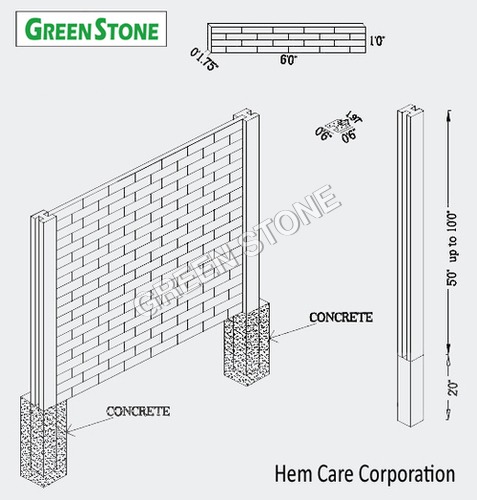

We manufacture high quality Pre-cast Boundary Wall mould. This Boundary Wall is made as per the clients requirements and specifications. We provide many type of pattern on boundary wall. Plain Boundary wall running, Plain Boundary wall with interlocking system (new Product), Different shapes as per customerrequirementwe prepare mould for boundary wall.

Product details

|

Material |

Iron |

|

Brand |

GreenStone |

|

Country of Origin |

Made in India |

|

Shape |

Rectangular |

|

Length |

7-10 Feet |

Exceptional Surface Finish and Durability

Achieve mirror-polished panels with every cycle, thanks to the moulds high-grade steel construction and meticulous finishing. The corrosion-resistant treatment ensures smooth productivity and long-term use, standing up to temporary temperatures as high as 350C without warping or deformation.

Versatile Applications and Customization Options

Perfect for construction, boundary walls, and fencing projects, this mould is available in both standard (e.g., 7 ft 1 ft) and bespoke sizes, with grooved design and panel thickness of 50 mm. You can customize patterns, colors, and other features to meet specific project requirements.

Ease of Operation and Low Maintenance

Designed for compatibility with vibration tables and both manual and automatic precast casting systems, this detachable and clamped mould simplifies installation and mobility. Maintenance is minimalcleaning is straightforward, and anti-rust coatings extend the operational lifespan far beyond 500 cycles.

FAQs of Precast Compound Panel Mould:

Q: How is the Precast Compound Panel Mould maintained for extended life?

A: The mould requires minimal maintenance; regular cleaning and prompt removal of concrete residue preserve its mirror-polished finish. Occasional inspections and proper storage enhance its lifespan, allowing it to reliably exceed 500 cast cycles.Q: What is the process for producing panels with this mould?

A: Place the mould on a vibration table, pour in wet concrete up to the 50 mm thickness, and use either manual or automated systems for casting. Once the concrete sets, the detachable design allows easy removal of the finished panel.Q: When should I choose customization for size or design?

A: Customization is ideal when your project requires panels outside the standard size (e.g., 7 ft 1 ft), or if you need a specific pattern, color, or finish. Custom options ensure each panel meets unique architectural or structural needs.Q: Where can the mould be used effectively?

A: The mould is perfect for use in construction sites, panel manufacturing facilities, and projects requiring boundary or fencing walls throughout India. Its rugged structure and mobility make it suitable both for stationary and dynamic workshop environments.Q: What are the key benefits of using this precast panel mould?

A: Key advantages include its reusability, high precision in panel reproduction, smooth surface finish, easy handling, and durability against heavy concrete loads (up to 1,200 kg). Low maintenance and anti-corrosion properties further enhance its value.Q: How does the joint type affect installation and usage?

A: With options for bolted or welded joints, the mould adapts to varied installation preferences. Bolted joints allow easy assembly and disassembly, while welded joints offer added rigidity for specific applications and higher cycle frequency.Q: What makes this mould compatible with vibration tables and casting systems?

A: The moulds robust, detachable design and reinforced steel structure allow secure placement on vibration tables, ensuring even concrete distribution and smooth panel surfaces. Its compatibility with both manual and automated systems broadens its usability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precast Wall Plant Category

Box Mould For Precast Wall Line

Price 90000-110000 INR

Minimum Order Quantity : 1 Unit

Features : Precision fabrication, anticorrosion finish, heavyduty clamps

Surface Treatment : Paint Coated

Usage : Used for forming/precasting concrete wall panels

Shape : Box/Rectangular

Box Mould for precast wall

Price 96000 INR

Minimum Order Quantity : 1 Unit

Features : Precision Machined, Corrosion Resistant, Easy Demoulding

Surface Treatment : Galvanized / Powder Coated

Usage : Precast Wall Panel Manufacturing

Shape : Rectangular / Square Box

PRECAST COMPOUND WALL / PANEL MOULD

Price 12500 INR

Minimum Order Quantity : 1 Unit

Features : Long life, Easy maintenance, Precise dimensions

Surface Treatment : Polished/Antirust Coated

Usage : Industrial precast panel production

Shape : Rectangular Panel Mould

Precast Compound Wall Design

Price 95000 INR / Unit

Minimum Order Quantity : 1 Set

Features : Weather resistant, termite proof, sound insulation

Surface Treatment : Smooth Finish / Paint Coated

Usage : Suitable for perimeter security and enclosure

Shape : Plain/Rectangular with pillar support

Send Inquiry

Send Inquiry