Call Us

08045476045

PRECAST COMPOUND WALL / PANEL MOULD

PRECAST COMPOUND WALL / PANEL MOULD Specification

- Color

- Silver/Grey

- Material Grade

- IS 2062 Grade Steel

- Thickness

- 40mm mould depth

- Application

- Precast Wall Panel Manufacturing

- Load Capacity

- Panel handling up to 250kg

- Features

- Long life, Easy maintenance, Precise dimensions

- Usage

- Industrial precast panel production

- Installation Type

- Portable/Movable Mould

- Machines Type

- Manual or Semi-Automatic compatible

- Form

- Rigid Mould

- Product Type

- Precast Compound Wall / Panel Mould

- Main Material

- High-grade Steel

- Surface Treatment

- Polished/Anti-rust Coated

- Size

- Standard panel size 1800mm x 300mm

- Weight

- Approx. 60-120 kg per mould

- Feature

- Reusable, Durable, High Precision

- Shape

- Rectangular Panel Mould

- Manufacturing Technique

- CNC precision machining

- Edge Profile

- Customizable as per requirement

- Cycle Time

- 30-60 minutes per panel

- Service Life

- 8-10 years under normal use

- Temperature Tolerance

- Up to 150°C during demoulding

- Packaging Type

- Wooden box/Bundle

- Number of Cavities

- Single or Multiple panel options

- Panel Finish Quality

- Smooth finish with sharp edges

- Handling Mechanism

- Integrated lifting hooks

- Resistance

- Corrosion and weather-resistant

- Joint Type

- Tongue & Groove compatible moulds

PRECAST COMPOUND WALL / PANEL MOULD Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- Unit

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About PRECAST COMPOUND WALL / PANEL MOULD

Assisted by the excellent support of our workforce, we are able to manufacture ad export a quality range ofPrecast Compound Wall Mould. Our offered product is known for its excellent strength, easy installation, superior durability and excellent working. Hugely demanded at the construction sites, this mould is used for the construction of compound wall and panels without any trouble. The pre casting makes the construction work easy and reduces the labor cost along with minimizing the processing time. We provide thisPrecast Compound Wall Mouldin different design and size at cost effective prices.

Features:

- Seamless finish

- Rust free

- Easy installation

GreenStone

Designer Mould

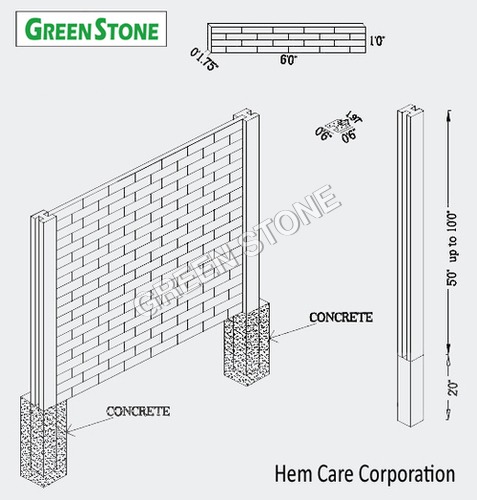

We manufacture high quality Pre-cast Boundary Wall mould. This Boundary Wall is made as per the clients requirements and specifications. We provide many type of pattern on boundary wall. Plain Boundary wall running, Plain Boundary wall with interlocking system (new Product), Different shapes as per customerrequirementwe prepare mould for boundary wall.

Product details

|

Usage/Application |

Designer Boundary Making |

|

Material |

Iron |

|

Country of Origin |

Made in India |

|

Brand |

GreenStone |

|

Length |

10-12 Feet |

High-Precision Manufacturing

Crafted using CNC precision machining, every mould achieves exceptional accuracy, ensuring smooth finishes and sharp panel edges. This advanced manufacturing process allows for precise customizations, such as edge profiles and joint types, supporting versatile precast wall design.

Enhanced Durability and Reusability

Manufactured from IS 2062 grade steel with polished and anti-rust coatings, the moulds withstand harsh weather and corrosion. Their robust construction and resistance ensure an extended service life of 810 years under standard industrial conditions, delivering excellent value for manufacturers.

Efficient Production and Handling

Designed for high productivity, each mould features integrated lifting hooks for easy and safe handling. The optimized cycle time of 30-60 minutes per panel boosts output, and the moulds portability supports both manual and semi-automatic operations, making it suitable for various factory setups.

FAQs of PRECAST COMPOUND WALL / PANEL MOULD:

Q: How is the PRECAST COMPOUND WALL / PANEL MOULD typically used in industrial production?

A: This mould is designed for manufacturing high-precision precast wall panels using concrete. Its robust construction, customizable features, and tongue & groove compatibility make it ideal for producing consistent panels in large volumes for construction and boundary wall projects.Q: What are the advantages of using a CNC-machined mould with integrated lifting hooks?

A: CNC machining ensures each mould achieves uniform dimensions and a smooth, sharp-edged finish, enhancing panel quality. Integrated lifting hooks facilitate safe and efficient handling during installation and demoulding, reducing manual labor and risk of damage.Q: When should I choose single versus multiple cavity options?

A: Single cavity moulds are suited for producing unique or custom panels, while multiple cavity moulds increase productivity during high-volume panel fabrication. The choice depends on your production scale and required flexibility within your manufacturing process.Q: Where can the mould be installed and operated?

A: This portable and movable mould is adaptable to various manufacturing setups. It suits both indoor and outdoor industrial environments and is compatible with both manual and semi-automatic precast machinery, making it accessible for diverse production requirements.Q: What makes this mould resistant to weather and corrosion?

A: The mould is made from IS 2062 grade high-grade steel and further protected by polished or anti-rust surface coatings. This combination offers excellent resistance against environmental elements, ensuring long-term structural integrity and minimal maintenance.Q: How long does each production cycle take and at what temperature can it be run?

A: Each panel can be produced in approximately 30-60 minutes, optimizing factory throughput. The mould tolerates temperatures up to 150C during demoulding, ensuring strength and maintaining panel finish even under demanding production conditions.Q: What are the key benefits of using this precast panel mould in wall panel manufacturing?

A: Key benefits include high durability, ease of maintenance, quick cycle times, customizable design features, and precise dimension accuracy. These facilitate efficient manufacturing, reduce operational costs, and ensure superior precast wall panel quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precast Wall Plant Category

Box Mould For Precast Wall Line

Price 90000-110000 INR

Minimum Order Quantity : 1 Unit

Shape : Box/Rectangular

Size : Customizable as per precast requirements

Feature : High durability, Reusable, Precision engineered

Features : Precision fabrication, anticorrosion finish, heavyduty clamps

Precast Compound Panel Mould

Price 12500 INR

Minimum Order Quantity : 1 Unit

Shape : Rectangular Panel Mold (with Grooved Design)

Size : Standard and Custom Sizes Available (e.g., 7 ft x 1 ft)

Feature : Reusable, Durable, High Precision

Features : Corrosion Resistant, Smooth Finish, High Strength

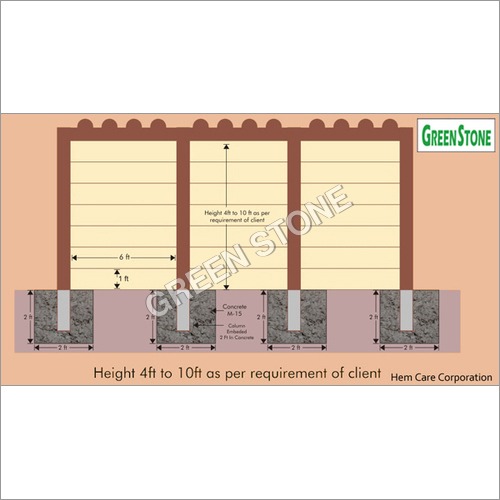

PRECAST COMPOUND WALL

Price 12500 INR / Unit

Minimum Order Quantity : 10 Units

Shape : Rectangular Panel

Size : 6 to 8 feet height, 6 feet width (standard panel size)

Feature : Ready to Install, Durable, Weather Resistant, Quick Construction

Features : Termite Proof, Fire Resistant, Maintenance Free

Precast Compound Wall Design

Price 95000 INR / Unit

Minimum Order Quantity : 1 Set

Shape : Plain/Rectangular with pillar support

Size : Height: 6 to 8 feet, Length: Customizable

Feature : Quick installation, durability, low maintenance

Features : Weather resistant, termite proof, sound insulation

Send Inquiry

Send Inquiry