Call Us

08045476045

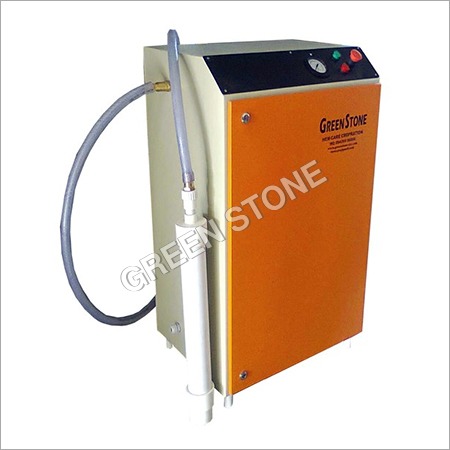

Lightweight Brick Making Machine

Price 1000000 INR/ Unit

Lightweight Brick Making Machine Specification

- Product Type

- Brick Making Machine

- General Use

- Brick making for construction

- Material

- Metal

- Capacity

- 1000-1500 bricks/hour

- Weight (kg)

- 350 kg

- Type

- Manual

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Method

- Manual operation with attached mixer

- Maximum Pressure

- 10 MPa

- Machine Power

- 5 kW

- Voltage

- 220V

- Dimension (L*W*H)

- Length: Approx. 2500mm Width: Approx. 1500mm Height: Approx. 1600mm

- Pallet Size

- 600mm x 400mm

- Minimum Height

- 50mm

- Maximum Height

- 300mm

- Number of Bricks

- 1-2 bricks per operation cycle

- Feature

- Lightweight construction manual operation

- Color

- Red and White

- Warranty

- 1 year

About Lightweight Brick Making Machine

Product Details:

| Capacity | 1000-1500 Blocks per hour |

| Block Type | Solid |

| Usage/Application | Brick Making |

| Method | Water Curing System |

| Material | Mild Steel |

| Brand | GreenStone |

| Country of Origin | Made in India |

| Automation Grade | Automatic |

Focused on technological up-gradation, dynamism and innovation, we are moving ahead by maintaining timeliness in delivering a wide gamut of Automatic CLC Block Making Machine. The offered machine is manufactured using high grade raw material and contemporary technology. We assure our clients that our machine is quality tested on predefined parameters, in order to meet industry standards. Apart from this, our prestigious clients can avail this machine, as per their needs, at highly competitive price.

Request

Callback

Efficient Manual Brick Production

This machine leverages manual operation, eliminating complex controls, and ensures consistent outputs ideal for small and medium-sized construction projects. With capacity to produce up to 1500 bricks per hour, it suits diverse operational needs without requiring automatic or computerized systems.

Robust and Portable Construction

Built from high-quality metal, our brick making machine is both sturdy and lightweight relative to its function. The compact design (2500mm x 1500mm x 1600mm) allows easy placement and repositioning, making it perfect for flexible deployment at various construction sites.

User-Friendly with Integrated Mixer

The attached mixer simplifies the material preparation process, allowing for seamless manual blending. Operators benefit from straightforward handling, enabling effective and efficient brick production with minimal training or technical expertise.

FAQs of Lightweight Brick Making Machine:

Q: How does the manual operation of this brick making machine work?

A: The machine requires the operator to manually feed raw materials into the attached mixer, blend them thoroughly, and then operate the mechanism to form and press 1-2 bricks per cycle. The process is straightforward and does not involve computerized or PLC controls.Q: What materials can be used with this brick making machine?

A: This machine is compatible with traditional brick-making raw materials such as fly ash, sand, cement, and aggregates commonly used in construction projects across India.Q: When is this machine most beneficial for construction projects?

A: The machine is ideal when consistent brick output is needed with limited operational complexity or automation. Its particularly useful for sites requiring flexibility and rapid production with manual oversight.Q: Where can this brick making machine be deployed effectively?

A: Thanks to its moderate size and lightweight construction, the machine can be stationed at construction sites, small manufacturing units, or locations where portable, manual machinery is preferred.Q: What is the step-by-step process for making bricks using this machine?

A: First, raw materials are added to the attached mixer and mixed. The blend is then placed into the brick mold. The machine is manually operated to press and form 1-2 bricks per cycle, which are then removed and readied for curing.Q: How many bricks can the machine produce per hour, and what are their dimensions?

A: Depending on operational speed, the machine can deliver between 1000 and 1500 bricks per hour. Each brick can be customized in height from 50mm to 300mm, using the 600mm x 400mm pallet.Q: What are the main benefits of choosing this lightweight manual brick making machine?

A: This machine offers simplicity, durability, minimal maintenance, and efficient brick production without the need for electronic controls. It comes with a one-year warranty and is tailored for Indian construction industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CLC Bricks Plant Category

CLC Blocks Plant

Price 450000 INR / Set

Minimum Order Quantity : 1 Set

Computerized : Yes

Automatic : Other, Fully Automatic

Product Type : CLC Blocks Plant

General Use : Production of lightweight concrete blocks (CLC Blocks)

CLC Bricks Making plant

Price 490000 INR

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Yes

Product Type : CLC Brick Making Plant

General Use : Making lightweight CLC (Cellular Lightweight Concrete) bricks

GREENSTONE PORTABLE FOAM-GENERATOR

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Product Type : GREENSTONE PORTABLE FOAMGENERATOR

General Use : Construction

Foam Generator For Clc Plant

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Product Type : Foam Generator For Clc Plant

General Use : Industrial

Send Inquiry

Send Inquiry