Call Us

08045476045

CLC Bricks Making plant

CLC Bricks Making plant Specification

- Product Type

- CLC Brick Making Plant

- General Use

- Making lightweight CLC (Cellular Lightweight Concrete) bricks

- Material

- Mild Steel / Stainless Steel

- Capacity

- 500-1000 Bricks/Hour

- Weight (kg)

- Approx 3500 kg

- Type

- Fully Automatic

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Method

- Autoclaved / Foam Concrete Technology

- Vibration Type

- Platform Vibration

- Vibration Frequency

- 2800-3100 rpm

- Maximum Pressure

- 80-120 Ton

- Machine Power

- 27-32 kW

- Voltage

- 380 V / 3 Phase / 50 Hz

- Dimension (L*W*H)

- 6250 x 1860 x 2360 mm

- Pallet Size

- 1200 x 850 mm

- Minimum Height

- 60 mm

- Maximum Height

- 220 mm

- Number of Bricks

- 16-20 Bricks/Batch

- Feature

- High efficiency, low maintenance, easy operation

- Color

- Grey and Green

CLC Bricks Making plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Packaging Details

- standard packing

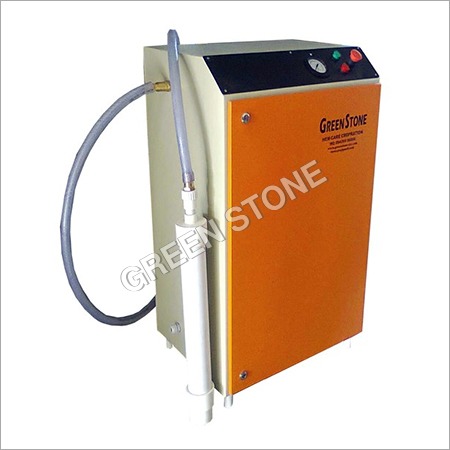

About CLC Bricks Making plant

Our company is widely appreciated in offering CLC Block Making Machines to the clients. CLC Block Making Machine is manufactured by using excellent quality material in accordance with the quality norms set by the industry. Our offered product is widely used in construction industries for making light weight blocks. This is highly admired for its quality and performance. CLC Block Making Machine is available at very low market prices with latest techonology.

Features:

- Superior functionality

- Negligible maintenance

- Sturdy construction

Specification

| Automation Grade | Automatic |

| Brick Type | Solid |

| Capacity | 1.2 m3 |

| Brick Raw Material | Fly Ash |

| Brand/Make | GreenStone |

| Country of Origin | Made in India |

Efficient Brick Production Technology

Employing foam concrete and autoclaved technology, this plant seamlessly integrates high-pressure platform vibration to ensure uniform density and strength across each batch. With the capacity to deliver 1620 bricks per batch in a rapid 1015 minute cycle, the system is ideal for high-volume demands.

User-Friendly and Fully Automated

Equipped with PLC-based computerized controls and straightforward operation, the plant requires just 12 operators per shift. Automated batching, mixing, and moulding functions ensure consistent product quality while minimizing labor and maintenance requirements.

Eco-Conscious Construction Solutions

Optimized for a variety of raw substances, including fly ash and foam, the plant supports greener building initiatives. Its substantial output and resource efficiency make it an excellent choice for construction companies seeking to combine sustainability with productivity.

FAQs of CLC Bricks Making plant:

Q: How does the CLC Bricks Making Plant operate and what process does it use?

A: The plant utilizes an autoclaved or foam concrete technology, combining fly-ash, cement, sand, water, and foam in a fully automated mixer with a PLC-based control system. Platform vibration at 2800-3100 rpm and high-pressure systems ensure each batch, processed in approximately 10-15 minutes, yields uniformly strong and lightweight bricks.Q: What raw materials are compatible with this plant and how do they benefit production?

A: This plant efficiently processes fly-ash, cement, sand, foam, and water, which are all commonly available materials. Utilizing these substances not only reduces environmental impact but also cuts production costs while maintaining structural quality and lightness in the resulting bricks.Q: What is the water and power requirement for each operating cycle?

A: Each cycle consumes about 300-350 litres of water and the total machine power required ranges between 27-32 kW, sourced from a standard 380 V, 3-phase, 50 Hz industrial supply. This ensures robust performance and steady production rates for industrial-scale operations.Q: When is it ideal to operate the CLC Bricks Making Plant?

A: The optimal operating temperature range is from 10C to 45C, making the plant suitable for most climate zones in India. This temperature flexibility allows continuous production throughout the year, maximizing efficiency.Q: Where can this plant be installed, and what space is required?

A: Due to its dimensions (6250 x 1860 x 2360 mm), the plant requires a spacious, level industrial area with access to industrial electric supply, water, and raw materials. Its robust build and design make it ideal for installation at manufacturing facilities, construction sites, or dedicated brick production workshops.Q: What are the primary benefits of using this automated plant?

A: Major advantages include high efficiency (500-1000 bricks per hour), reduced labor with only 1-2 operators needed, consistent quality due to PLC control, low maintenance, and support for environmentally friendly raw materials, contributing to greener construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CLC Bricks Plant Category

Foam Generators

Price 150 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Computerized : No

Type : Other, Horizontal / Portable

Material : Other, Mild Steel (Powder Coated)

CLC Brick Machinery

Price 450000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : AAC Plant

Material : Stone

Foam Generator For Clc Plant

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Semi Automatic CLC Brick Making Machine

Price 490000 INR

Minimum Order Quantity : 1 Set

Computerized : No

Automatic : No

Type : AAC Plant

Material : Fly Ash

Send Inquiry

Send Inquiry