Call Us

08045476045

Foam Concrete Blocks MAKING MACHINERY

Price 50.00 INR/ Unit

Foam Concrete Blocks MAKING MACHINERY Specification

- General Use

- Industrial

- Computerized

- No

- Automatic

- No

- Color

- Grey

- Warranty

- Yes

Foam Concrete Blocks MAKING MACHINERY Trade Information

- Minimum Order Quantity

- 1200 Units

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 7 Days

About Foam Concrete Blocks MAKING MACHINERY

Gratifying the current industry as a manufacturer, supplier and exporter, we are presenting an excellent array of Foam Concrete Blocks. CLC is full formed as Cellular Weight Concrete that is considered as a light version of concrete or reduced density concrete. Mainly, the provided range is meant as cement based slurry comprising minimum 20% volume of foam that is entrained into plastic mortar. The composition of Foam Concrete Blocks contain slurry of cement and fly ash or sand and water that is further mixed with synthetic aerated foam to provide strong structure.

Features:

- Faster construction

- Less water consumption

- Light weight

Cellular Light Weight Concrete

CLC

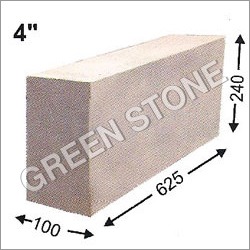

4 X 24 X 8

Cellular Light Weight Concrete (CLC) is a version of light concrete that is product like normal concrete under ambition by initially making slurry of cement + flyash + water + Pre-formed stable foam. The foam imparts free flowing characteristic to this slurry due to ball bearing effect of foam bubbles enabling it to easily flow into all corners and compact by itself in the moulds.

Specification

|

Material |

Cement |

|

Brand |

GreenStone |

|

Shape |

Rectangular |

|

Color |

Gray |

|

Usage/Application |

Side Walls |

|

Size (Inches) |

4 x 8 x 24 Inch |

|

Resistance Durability |

Fire Resistant |

|

Automation Grade |

Semi-Automatic |

|

Eco Friendly |

Yes |

|

Country of Origin |

Made in India |

Industrial-Grade Durability and Quality

Engineered for industrial environments, our foam concrete blocks offer exceptional strength and reliability without relying on computerized or automatic equipment. Each block is manufactured under strict quality checks to ensure consistency and long-term performance, making them a trusted choice for large-scale projects across India and abroad.

Comprehensive Export and Supply Solutions

As a dedicated exporter, manufacturer, supplier, and trader, we provide tailored foam concrete block solutions to meet diverse industry needs. With a focus on punctual delivery and customer satisfaction, we support projects across domestic and international markets, guaranteeing product authenticity and seamless service.

FAQs of Foam Concrete Blocks:

Q: How are your foam concrete blocks manufactured without computerized or automatic machines?

A: Our foam concrete blocks are crafted using manual yet precise processes, ensuring each unit adheres to rigorous quality standards. Skilled technicians oversee every step, maintaining high consistency and reliability in the final product.Q: What are the typical uses for these foam concrete blocks in industrial settings?

A: These blocks are widely used for constructing partition walls, thermal insulation, and soundproofing in factories, warehouses, and other industrial structures due to their lightweight and robust properties.Q: When can I expect delivery of foam concrete blocks if ordered as an exporter or supplier in India?

A: Delivery timelines depend on order volume and destination, but we prioritize prompt dispatch and offer efficient shipping both domestically and internationally. Our team communicates closely with clients to ensure reliable delivery schedules.Q: Where are your foam concrete blocks available for purchase?

A: Our foam concrete blocks can be procured directly through us as a manufacturer, as well as via our network of suppliers and traders across India. We also serve global markets through our export services.Q: What is the process for ordering foam concrete blocks in bulk?

A: To place a bulk order, customers can contact our sales team with their specifications. We provide tailored quotations, manufacturing schedules, and organize logistics for efficient fulfillment.Q: How should foam concrete blocks be handled and installed on construction sites?

A: Due to their lightweight design, these blocks are easy to transport and install. We recommend manual handling with standard safety precautions, and following common masonry practices for best results.Q: What are the primary benefits of using your foam concrete blocks?

A: Our foam concrete blocks offer excellent thermal and acoustic insulation, reduce structural load thanks to their light weight, and contribute to faster construction methods. Additionally, all units come with a warranty for customer assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CLC Bricks Plant Category

Lightweight Block Making Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : No

Product Type : Block Making Machine

Feature : Other, Lightweight, Energy Efficient, Easy Operation

CLC Bricks Making plant

Price 490000 INR

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Yes

Product Type : CLC Brick Making Plant

Feature : Other, High efficiency, low maintenance, easy operation

CLC Brick Machinery

Price 450000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Low Weight, Fire Resistant, Anti Seismic, High Durability

GREENSTONE PORTABLE FOAM-GENERATOR

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Product Type : GREENSTONE PORTABLE FOAMGENERATOR

Feature : High Durability

Send Inquiry

Send Inquiry