Call Us

08045476045

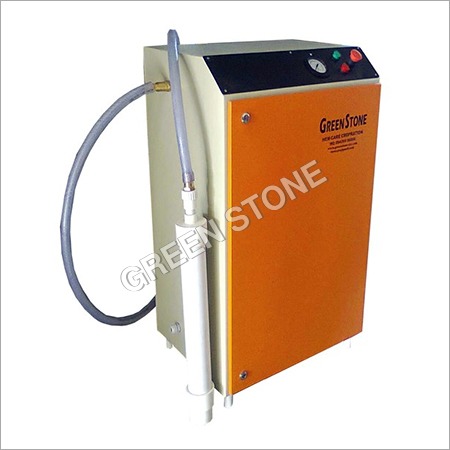

Semi Automatic CLC Brick Making Machine

Semi Automatic CLC Brick Making Machine Specification

- Product Type

- sami auto

- Material

- Fly Ash

- Capacity

- 1m3 Kg/hr

- Weight (kg)

- 1500 Kilograms (kg)

- Type

- AAC Plant

- Computerized

- No

- Automatic

- No

- PLC Control

- No

Semi Automatic CLC Brick Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Main Domestic Market

- All India

- Certifications

- iso 9001:2015

About Semi Automatic CLC Brick Making Machine

- Light in Weight

- Eco Friendly

- Sound Insulation

- Lower Water Absorption

- Fire Protection

- Uniform Mixing of Foam in Cement / Fly Ash Slurry

- Specially designed Electric panel which controls the Mixing

- specially designed foam generator to get best quality of foam with good stability

- Getting uniform CLC Blocks without varation of Height and weight

- Size: 600 X 200 X 100 mm

- Size: 600 X 200 X 150 mm

- Size: 600 X 200 X 200 mm

Product details

| Automation Grade | Semi-Automatic |

| Brick Type | Solid |

| Brand | GreenStone |

| Capacity | 1.2 m3 |

| Material | Mild Steel |

| Brick Raw Material | Fly Ash |

| Country of Origin | Made in India |

Efficient and Consistent CLC Brick Production

Our Semi Automatic CLC Brick Making Machine offers reliable and consistent production of lightweight CLC bricks using fly ash. Built to withstand intensive use, it maintains uniformity in output, making it ideal for small to medium-scale construction projects.

Eco-Friendly Construction Solution

By utilizing fly ash, this machine helps reduce industrial waste and supports sustainable construction practices. The resulting CLC bricks are known for their excellent insulation, promoting energy-efficient buildings.

FAQs of Semi Automatic CLC Brick Making Machine:

Q: How does the Semi Automatic CLC Brick Making Machine operate without PLC control?

A: The machine is designed for semi-automatic operation, meaning it requires manual intervention for certain steps, but still maintains a streamlined process. It does not include a PLC (Programmable Logic Controller), relying on manual or mechanical controls, making it easier to operate and maintain.Q: What raw materials are required for this CLC brick making machine?

A: This machine primarily uses fly ash as the main raw material for producing Cellular Lightweight Concrete bricks. Other ingredients such as cement, foaming agents, and water may also be mixed as required by the process.Q: When is this machine recommended for use in construction projects?

A: The Semi Automatic CLC Brick Making Machine is best suited for small to medium-scale projects where moderate automation is sufficient, and significant investment in fully computerized equipment is not required.Q: Where can this machine be sourced in India?

A: The machine is available through various exporters, manufacturers, suppliers, and traders located across India, allowing for easy procurement and support within the country.Q: What is the typical process for making bricks using this machine?

A: The process involves mixing fly ash, cement, foaming agent, and water, which are then poured into the machines mold system. The semi-automatic controls facilitate proper mixing and molding. After setting, the bricks are removed and allowed to cure before use.Q: How are CLC bricks produced by this machine typically used?

A: CLC bricks manufactured with this machine are used in partition walls, filling walls, and non-load-bearing structures due to their lightweight nature and thermal efficiency.Q: What are the main benefits of choosing this semi automatic CLC brick making machine?

A: Key benefits include reduced operational costs, eco-friendly production utilizing fly ash, easy maintenance, and consistent quality output, making it an excellent choice for sustainable and economical construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CLC Bricks Plant Category

Lightweight Block Making Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Feature : Other, Lightweight, Energy Efficient, Easy Operation

Automatic : No

Computerized : No

CLC Blocks Plant

Price 450000 INR / Set

Minimum Order Quantity : 1 Set

General Use : Production of lightweight concrete blocks (CLC Blocks)

Feature : Other, Energy efficient, low maintenance

Automatic : Other, Fully Automatic

Computerized : Yes

CLC Brick Machinery

Price 450000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Low Weight, Fire Resistant, Anti Seismic, High Durability

Foam Generator For Clc Plant

Price 62000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Feature : High Durability

Automatic : Yes

Computerized : No

Send Inquiry

Send Inquiry